EXTRUSTION BLOW MOULDING

We specialise in blow-molded bottles, containers, and shapes that are bespoke. We are committed to a world-class quality management system at Chemco Plast, which enables us to provide excellent customer service and quick turnaround for short-to-medium production runs. We can blow mould for almost any application and level of intricacy, from bottles of 5 ml to 5000 ml capacity and in a number of combinations. We have over 21 extrusion blow moulding machines to serve our clients.

INJECTION BLOW MOULDING

The injection blow molding (IBM) process produces billions of plastic containers each year. Ranging in size from 1 ml to 2 liters, these containers meet exacting standards of consistent weight, volume and tolerance, and are popular around the world for a myriad of applications from pharmaceuticals to toiletries to automotive to household use. We have two injection blow moulding machines for cost effective production and premium quality for our customers

IBM Bottle attributes

- Exact Neck dimensions

- Thick, even walls

- Nearly invisible parting lines

- Variety of different finishes are possible

INJECTION MOULDING

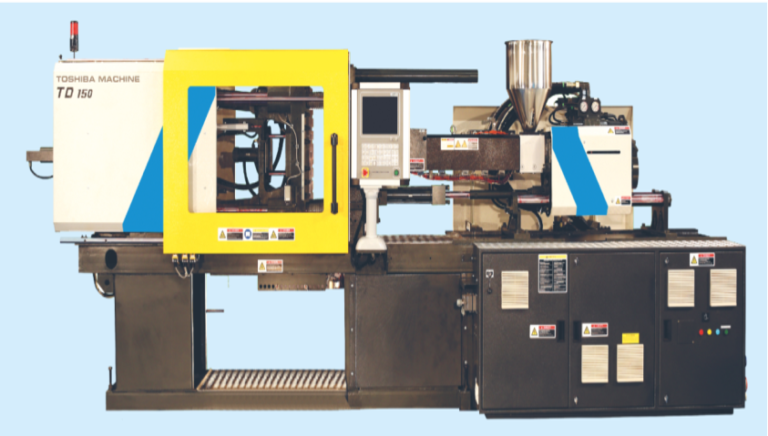

We have the latest machinery with programmable microprocessor available in our production department, which helps us achieve high quality standards. Our expertise in the different types of molds including hot runner and insert molding enables us to handle low or

high volume production. In addition, some of our machines are equipped with the capability of employing robotic control for efficient molding and reduced cycle times.

We have over 20 injection molding machines that are all electric to serve the customers’needs. For high precision small components, our manufacturing /production facility uses TOYO machines for best quality and precision. The production capacity of our machines

ranges from 40 tonnes to 400 tonnes of clamping force.